There is a term in Japan called Kaizen. It’s a philosophy that emphasises making small, incremental changes to processes to achieve significant long-term gains in performance.

Hailing from the manufacturing world, Kaizen makes manual labour tasks more efficient, e.g, placing a benchtop with one component closer to the assembly line reduces the number of steps needed to grab that component.

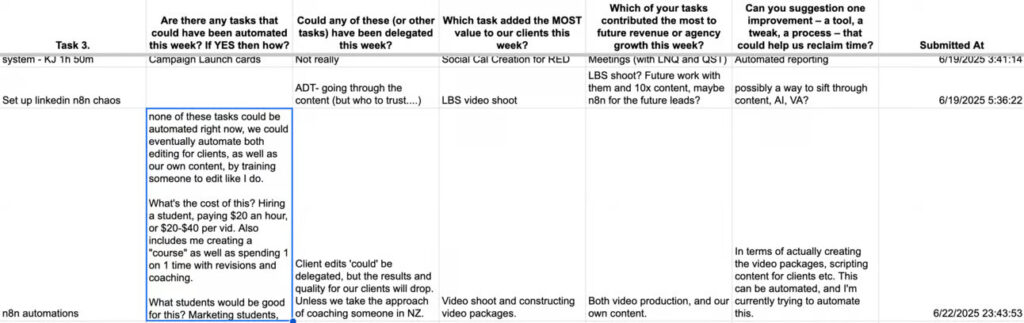

We’ve introduced a 5-minute audit following the Kaizen process for the knowledge work that we do at K&J to identify the following:

-

The three biggest time sucks from the previous week

-

What part of these time sucks could be automated

-

The one task that a team member completed that they believe added the most value to our clients

-

The one task they believed added the most value to the business

After getting the results of these questions, I’ve spotted a few trends:

-

We do a lot of manual work that needs tighter processes – essentially, we’re wasting time & money in certain places

-

Tasks that I believed took only 30 minutes actually required hours to complete – I’m misunderstanding the time demands of our team

-

Things that people believe are adding value to the business are different to where I think they are adding value to the business – I’m not communicating where the value lies in the roles they are playing in our business

Co-author Rhys said this to me a couple of weeks back.

This weekly audit allows our business to get closer to this outcome. Great companies get everyone rowing in the same direction, faster and more efficiently week on week.

Try using these questions this week to see if your business is doing this. You can copy them here.